For heavy original equipment manufacturers who want to focus their resources on the marketing and engineering of their products, our manufacturing organization possesses a comprehensive set of capabilities that provide a single source for all of your production needs. Unlike using multiple suppliers for each type of component or operation, our manufacturing capabilities provide a turnkey solution for your production outsourcing needs.

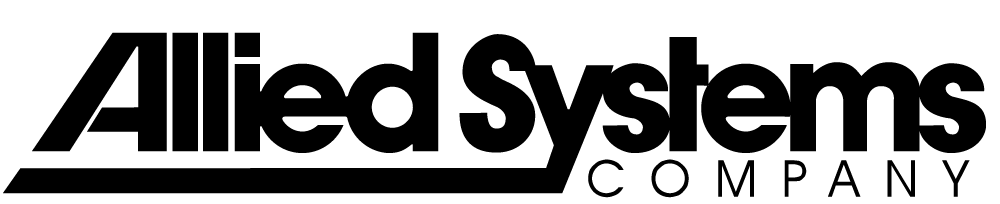

Fabrication

![]() Allied Systems Company is capable of burning, cutting, bending, rolling and welding very large structural components. We are able to offer our OEM customers large, high quality product components on a timely basis, helping you manage your internal resources and serve your customers more efficiently. If you don't possess the large-scale fabrication capabilities necessary, or simply want to improve your operational efficiency, Allied Systems is your fabrication solutions provider.

Allied Systems Company is capable of burning, cutting, bending, rolling and welding very large structural components. We are able to offer our OEM customers large, high quality product components on a timely basis, helping you manage your internal resources and serve your customers more efficiently. If you don't possess the large-scale fabrication capabilities necessary, or simply want to improve your operational efficiency, Allied Systems is your fabrication solutions provider.

-

Burn Tables

- HD Plasma up to 2" thick

- Oxy-Fuel over 2" up to 4" thick

- 23' by 10' plate size capacity

- 8 ton capacity 120 Ton Punch Capacity Sawing

- Up to 18" maximum height Brake Press

- 16' machine length, 600 tonnage Rolling or Bending

- 48" capacity Welding

- Can weld up to 6" thick plate FCAW, MIG and TIG Welding Materials

- A514

- A572 (Grade 50)

- A36

- Aluminum

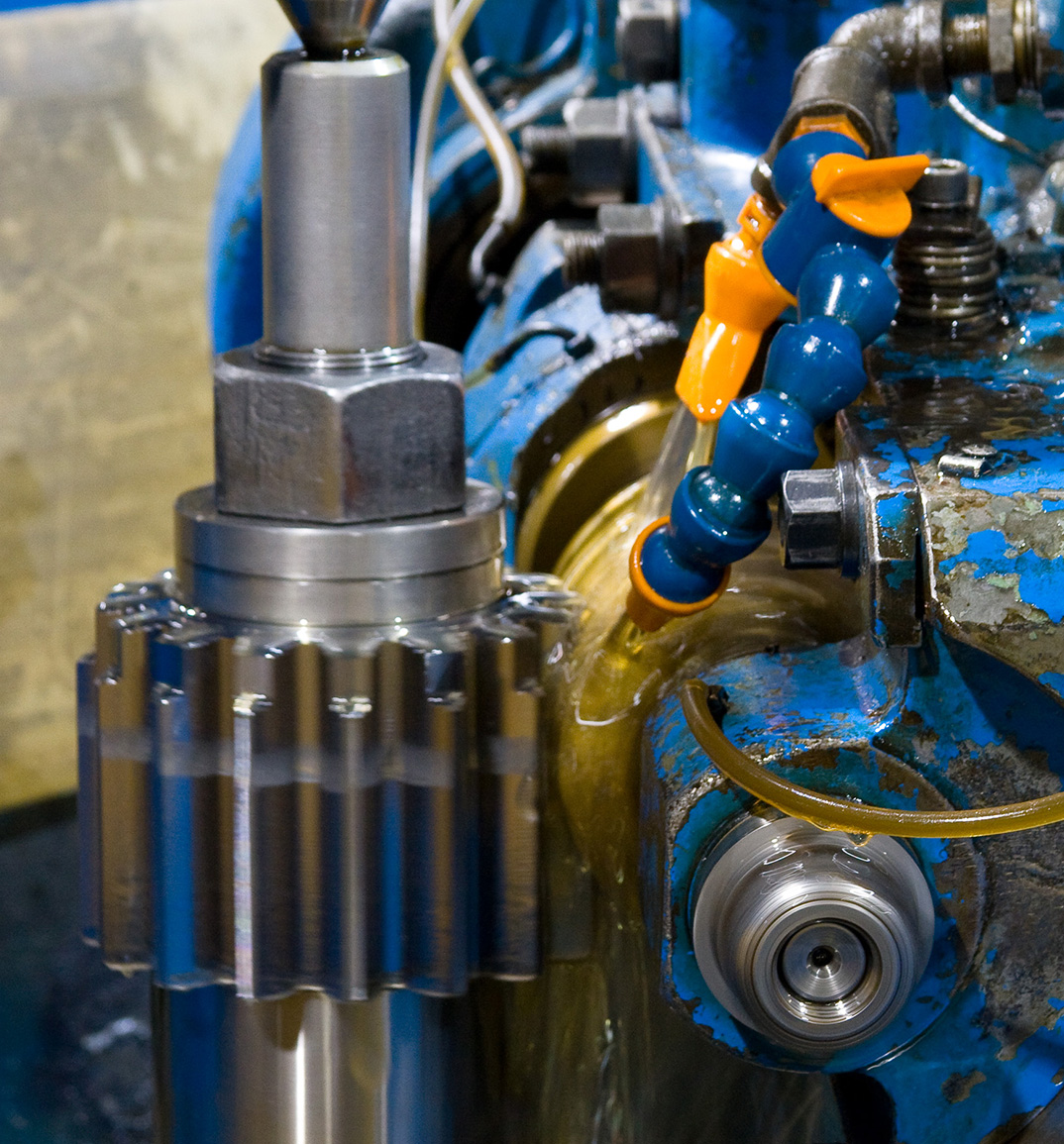

Machining

![]() Allied Systems operates a full service machine shop, featuring 13 CNC mills and 8 CNC lathes. If you are in need of specialized machined components for your finished product, Allied Systems is the contract manufacturer for you. We are capable of drilling, broaching, gear cutting, milling and turning very large components. If you need a

machined component for your own

product or as part of an assembly,

Allied Systems can help.

Allied Systems operates a full service machine shop, featuring 13 CNC mills and 8 CNC lathes. If you are in need of specialized machined components for your finished product, Allied Systems is the contract manufacturer for you. We are capable of drilling, broaching, gear cutting, milling and turning very large components. If you need a

machined component for your own

product or as part of an assembly,

Allied Systems can help.

-

Gun Drilling

- 9/16" maximum diameter

- 17.125" maximum depth Broaching - 18.25" maximum diameter Gear Hobbing - 48" maximum diameter (1DP) Gear Shaping - 36" maximum diameter (4 DP) Milling

- Up to 160" maximum x-axis

- Up to 72" maximum y-axis

- Up to 120" maximum z-axis

- Some CNC mills have pallet changers Vertical Turning - 52" swing, 45" height Horizontal Turning - Up to 28" swing, 144" bed length

- Lathes with live tooling capability Cranes

- Up to 20 ton single pick capacity

- Up to 45 ton dual pick capacity Sandblast

- 52' length 23' width 25' door height Four Paint Booths

- 66' length, 25' width, 25' door height

Final Assembly/Finishing

Allied Systems operates an 84,000 square foot final

assembly facility. Whether your product needs to

be assembled and finished after Allied Systems

has fabricated and/or

machined the parts, or

you simply need a large

enough booth for your

product to be sandblasted

and painted,

Allied Systems can

handle all of your

assembly and painting

requirements.

Allied Systems operates an 84,000 square foot final

assembly facility. Whether your product needs to

be assembled and finished after Allied Systems

has fabricated and/or

machined the parts, or

you simply need a large

enough booth for your

product to be sandblasted

and painted,

Allied Systems can

handle all of your

assembly and painting

requirements.

Quality Built Products

Allied Systems is committed to providing quality products for our contractors. Our team's experience and exceptional attention to detail ensures reliablity in everything we build. With a quality system based on the requirements of API Specification Q1 (see certificate), you can rest assure that every machine and part we build is tested, documented, and ready to meet your specific needs.

USCG

International Maritime Organization

American Bureau of Shipping

Det Norske Veritas

Lloyds Register of Shipping