December 2014, Vol. 33 No. 3

The H4H winch with optional fairlead on Case 750M.

The same winch fits the 850M with no modification.

New Case M Series Finding Success with Allied Winch

Case recently announced the new M Series line of crawler dozers, and Allied was there to join the party. Winch shipments for the new machines have been exceeding all expectations.

The new Case models have been receiving rave reviews from both customers and operators. Customers have been impressed with the power and ease the combination provides.

Most dealers are familiar with Allied’s PTO-driven winches that have been the mainstay in the winch business for decades. Starting with the M Series, all winches for Case dozers are now hydraulic winches. Here are the winches that match the Case line-up, which includes the 650L in addition to the new M Series models:

| Dozer | Winch |

|---|---|

| 650L | H4A |

| 750M | H4A |

| 850M | H4A |

| 1150M | H5C |

| 1650M | H5C or H6H |

| 2050M | H6H |

Let’s take a look under the hood of this new type of winch.

Hydraulic Winch Technology

An important thing to understand about any winch is that a winch has no power of its own. It’s more or less like a transmission, with power input on one side and an altered form of power out the other side. The input power is derived from any source that can ultimately be converted to torque at an input shaft. The most likely sources are mechanical (a PTO shaft directly or indirectly connected to a diesel or gasoline engine), hydraulic (the output shaft from a hydraulic motor), or electrical (the output shaft from an electric motor). That input power is then sent through a gear train to turn the winch drum. The gear train reduces the RPM and increases the torque to permit high line pull in the wire rope wrapped around the drum.

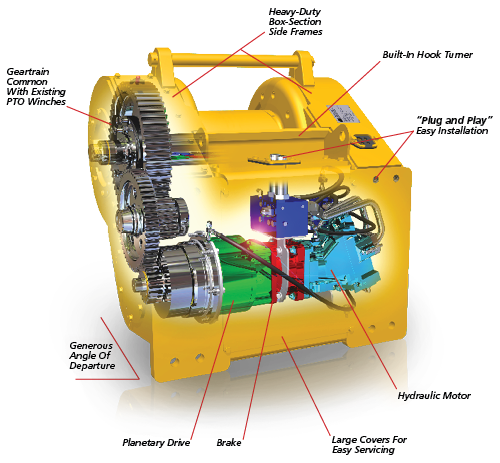

Inside the H6H hydraulic winch

Let’s look inside the H6H winch for 2050M to see a typical arrangement of our hydraulic winch. The input power comes from hydraulic flow delivered by the ripper hydraulic circuit, which itself is produced by a hydraulic pump on the Case dozer. The hydraulic input to the winch is sent to a hydraulic motor located securely inside the winch. The motor is connected to a brake, a planetary gearset and a brake-off clutch. All of these components are on a single shaft oriented across the winch. The output end of this shaft connects to the traditional spur gear train seen in our PTO winches, and then on to the drum. As the drum turns, the wire rope moves either toward the winch or away from the winch.

The control of this winch is provided by the ripper handlever. The handlever controls the direction and rate of flow, and can be metered precisely to cause the drum to turn slowly for exact positioning of the wire rope on the drum. The control is different on the H4A winch, but the result is the same.

Allied supplies additional electrical controls to supplement the ripper handlever. Depending on the winch model and options, these controls may include freespool, brake-off and a speed selection switch.

Each of the three winch models is a bit different. Let’s take a look one-by-one.

H4A winch for 650L, 750M, 850M

The H4A winch uses a unique approach for obtaining power from the Case dozers. Our design, called self-contained hydraulics (SCH), is the only one of its kind in the industry. The winch uses a closed-loop hydrostatic design that harnesses nearly 100 percent of the engine horsepower in the most efficient manner possible. The only connections to the dozer are through the PTO shaft and the handlever controls, both supplied by Allied. The result is a high-performance winch that installs quickly and has no connections to the dozer hydraulic system.

Inside the winch are housed both the hydraulic pump and hydraulic motor. The PTO shaft connects directly to the pump, and the pump is closely coupled to the hydraulic motor. Via the gear train, the motor applies power to the drum.

While our other winch models are driven by some form of the ripper circuit, this one is not. A winch driven by ripper hydraulics on the 650L, 750M and 850M would never realize the performance of the H4A winch with our exclusive SCH design.

Because ripper hydraulics are not involved, the H4A comes with its own control system. We supply a pilot-control handlever that communicates with the winch to control its power-in and power-out functions. We supply an electrical switch to control freespool operation.

For more information on the H4A winch, see this link: http://www.alliedsystems.com/pdf/Winch/Forms/86-xxx/86-646.pdf

Order the PTO Option 784730 for a new factory order or Dealer Installed Accessory Kit 47423045 for installing the PTO in the field. The cab needs a rear screen, to protect the operator in the event the winch wire rope breaks under tension.

The H5C winch with optional fairlead on the Case 1150M.

H5C for 1150M, 1650M

The H5C winch derives power directly from the ripper circuit of these dozer models. Its design is similar to the H6H winch described above. The ripper hydraulics on the larger Case M Series dozers have enhanced pressure and flow for higher winch performance.

The H5C is appropriately sized for all 1150M applications. For 1650M, the winch is considered a lighter-duty choice, where usage is less frequent or limited to rescue applications. For heavy line pull and frequent use, the H6H winch is a better choice.

On 1150M, order the Winch-ready option 784604. You will also need Rear Screen, either 784508 for cab unit or 784569 for ROPS unit. If you have a non-Winch-ready dozer, Case Dealer Installed Accessory Kit 47756296 contains the items needed to make it Winch-ready.

On 1650M, order it with the Winch-ready option 784604 and Rear Screen 784508. If you have a non-Winch-ready dozer, Case Dealer Installed Accessory Kit 4749236 has the components to make it Winch-ready.

The H6H winch on Case 1650M.

The same winch can be installed on the 2050M without modification.

H6H for 1650M, 2050M

Winching applications in North America are concentrated in the energy sector, involving oil and gas exploration, drilling and extraction, pipeline construction, wind turbine sites and the laying or stringing of electrical and fiberoptic cables. The 2050M is squarely in the size range most commonly used in this market segment, and represents the area of highest potential for new business for winch tractors. The H6H winch has proven to be the best accepted winch in this market segment. With the advanced performance and features of the 2050M, backed by the H6H winch, you have an important and profit-rich window of opportunity to win new business from this market.

The H6H winch has proven to be the hydraulic winch of choice in this market segment. Introduced in 2011, it now has been installed on several thousand dozers. It’s already helping Case dealers make significant inroads into this key market.

On 1650M, the H6H winch requires the same options as for the H5C winch. Order it with the Winch-ready option 784604 and Rear Screen 784508. If you have a non-Winch-ready dozer in stock, Case Dealer Installed Accessory Kit 4749236 will have what you need to make it Winch-ready.

On 2050M, use the same options as for 1650M, Winch-ready option 784604 and Rear Screen 784508. Use Case Dealer Installed Accessory Kit 47491859 to make it Winch-ready.

Take Advantage of Factory Winch Installation

Allied now offers factory installation of the Allied winch. We can ship your winch to Paladin, near the Calhoun plant, and have it installed there. For a single fixed cost known from the outset, you get winch freight to Paladin, dozer freight to Paladin and installation from an experienced team. If you ship wire rope with your winch, Paladin will spool the wire rope onto the winch drum for no additional charge.

See or download the flyer on winch installation from our website: http://www.alliedsystems.com/pdf/Winch/Forms/86-xxx/86-639.pdf

Get More Information

If you are new to winches, be sure to call Allied for more detailed explanation on any point about these winches. It’s a competitive environment, and you need to be informed to sell effectively.

You can download the spec sheet at this link: http://www.alliedsystems.com/pdf/Winch/Forms/86-xxx/86-506.pdf.

We’ll provide whatever additional information you need.