Success breeds success. Following hard on the heels of the very successful H6H hydraulic winch, the new H8L and H12E winches are now available. Both winches are based on the successful PTO winch platforms, the W8L and the W12E. At the high end of the line is the new H12E winch, rated at 120,000 lbs line pull. The new H8L winch completes the hydraulic winch line in the 80,000-lb class, filling in between the H12E and the H6H.

The design approach and key technologies are similar to the H6H winch, introduced in 2010 (see Winchlines, Vol. 29, No. 1). The state-of-the-art design and hydraulic components match up beautifully with the new generation of hydrostatic dozers.

In the two winch families—PTO and hydraulic—there is a winch in every size class from 30,000 lbs. to 120,000 lbs. line pull rating. The table on the next page shows the current tractor models and the appropriate winches that support these models. This represents the most complete offering of rear-mounted towing winches in the industry.

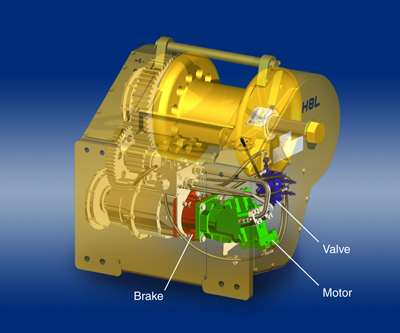

The starting point for both hydraulic winches is the PTO winch of the same size, not a repurposed planetary winch more suited to a stationary application. A high-performance hydraulic motor, planetary gear set, brake and brake-off clutch replace the powershift clutches and brake found in the PTO winch. The classic wedge shape of the winch is retained. The same fairlead can be fitted to the same size winch in either family.

The H8L and H12E use a heavy-duty bent-axis, variable displacement piston motor to support the higher pressure requirements of the new generation of hydrostatic dozers. This motor provides a continuously variable speed control to the wire rope, which helps the operator set the load precisely. The control logic in the winch responds quickly to the imposed load, delivering the best motor setting for the pulling requirement at that moment. The motor is inside the winch frame, safely tucked away from damage.

Like the H6H, the H8L and H12E winches come with brake-off, achieved through an oil-bath, multi-disc brake-off clutch. The brake-off function allows the tractor to drive away from the tethered load while keeping the wire rope taut, to prevent the wire rope from "bird-nesting." This helps increase productivity in areas with poor ground conditions.

The H8L and H12E winches both use the "plug-and-play" design. The winch comes with everything required for a complete and tidy installation. Installation time for the winch is quick. Just bolt the winch to the dozer rear face and connect the hydraulic lines and you're on your way.

The first installation of the H8L winch was on the Cat D7E track-type tractor. This unique tractor is driven by electric motors. It has standard hydraulics for key tractor functions such as blade and ripper. The D7E comes standard with high-performance hydraulics delivered to a manifold at the rear face for either ripper or winch. The Allied winch is supplied with all hydraulic parts needed to connect directly to the D7E manifold with no winch-ready option needed, a true "plug-and-play" installation. Controls are electric over hydraulic using a control lever and switches supplied with the winch for installation on the operator console. Cat dealer Pipeline Machinery International (PLM) sent a D7E to Allied to have their new H8L winch installed here prior to delivery.

The first H12E installations on Komatsu dozers were on the D275AX-5 and D155AX-6. These dozers are equipped with rear hydraulics as a standard feature. Winch control is through the standard ripper control handlever. The winches are supplied with all hydraulic components for a "plug-and-play" installation. Komatsu America Corp. provided a D275 for winch fit-up at Allied.

Complete specifications on the new H8L and H12E winch are available here. Please contact us at +1-503-625-2560 or marketing@alliedsystems.com for more information on these impressive new winches.

PTO Winch Family |

|||||

|

W3C |

W5C |

W6F/G |

W8L |

W12E |

Cat |

D3/4/5C |

D5N |

D6R/T |

D7R |

D8/9/10T |

D6N |

D7G |

||||

D6N |

527 |

572R |

583T |

||

Komatsu |

D39-21 |

D61-15 |

D61-15 |

D85-15 |

D155-2 |

D65-15 |

D85ESS-2 |

D275-2 |

|||

John Deere |

~ |

700J |

750C |

~ |

~ |

850C |

|||||

Case |

650-850K |

1150K/H |

1650K/L |

~ |

~ |

750-850L |

1650K/L |

1850K |

|||

New Holland |

DC85-95 |

D150 |

D180 |

D255 |

D350 |

Dressta |

TD7-10M |

TD14 |

TD15 |

TD20 |

TD25 |

Shantui |

~ |

~ |

SD-16 |

SD-20 |

~ |

Hydraulic Winch Family |

|||||

|

H4A |

H5C |

H6H |

H8L |

H12E |

Cat |

D3/4/5K |

D6K |

D6T |

D7E |

D8T |

D3/4/5G |

PL61 |

||||

Komatsu |

D39-22 |

D51-22 |

D65-16/17 |

D85-15 |

D155-6 |

D275-5 |

|||||

John Deere |

~ |

700J |

750J |

950J |

1050J |

750J |

850J/K |

||||

Case |

650-850K/L |

~ |

~ |

~ |

~ |

New Holland |

DC75-95 |

~ |

~ |

~ |

~ |

Liebherr |

~ |

~ |

724 |

734 |

~ |

The H8L "Plug and Play" winch can be installed on any D7E with no need for winch-ready package.

The Allied team is pleased to show off the results of their installation project, the first H12E hydraulic winch, on Komatsu D275.

The H12E makes use of the D275 ripper pin mounting for quick installation.

"Plug and Play" hydraulic winches make installation easy. Motor, control valve, and brake are well protected inside frame.