No doubt about it, the Allied hydraulic winches demonstrate an amazing level of versatility and adaptability. Take a look at these interesting new winch applications:

Caterpillar 963D Track-Type Loader

A modern track loader is not an easy machine for adding a rear-mounted towing winch. Instead of a vertical rear face as usually seen on a crawler dozer, it has a rear-mounted engine, radiator and counterweight where a winch would be installed. Little details like that did not stop Fabick Cat of Missouri USA from supplying their customer with a new 963D track loader with rear-mounted Allied H6H winch. Working closely with Allied for technical support, the Fabick team developed a mounting bracket to secure the winch to the rear frame. They used the standard ripper hydraulic circuit to power the winch, needing only to develop the connecting hoses to complete the hydraulic system. (See also the Allied winch on John Deere 755C track loader in Winchlines, Vol. 26 No. 2.)

One challenge for this type of installation is that the operator is unable to see the winch when sitting at the controls. Fabick sourced a closed-circuit video camera to mount above the winch and a display screen to mount inside the cab.

The 963D with winch will find a wide variety of uses in oilfield applications. The winch gives the operator greater confidence in tackling more difficult ground conditions, knowing that self-rescue and equipment rescue are at the tips of the fingers.

Liebherr PR724 Crawler Dozer

Liebherr, a diversified manufacturer of heavy equipment, cranes and hydraulic equipment based in Europe, has been supplying hydrostatic crawler dozers since 1972. Their dozers have been widely used in Europe for many years, and are starting to make a stronger entry into the North American market. No surprise that a winch requirement would arise before too long. Liebherr dealer RECO Equipment in Ohio USA needed a winch on a PR724 dozer. The Allied H6H winch was the perfect size, well-known in the North American market, and readily adaptable. Working closely with Liebherr Engineering in Telfs, Austria, Allied developed a specific mounting bracket and hydraulic arrangement for this dozer model. For the first installation, Allied engineering staff was on-site to verify the fit-up and operation of the winch.

This is just the beginning of a more complete winch offering on Liebherr dozers. Look for additional news later this year.

Caterpillar D6T Track-Type Tractor

The Cat D6T is normally outfitted with the Allied W6G PTO-driven winch. An electrical utility service contractor had been using the Allied H6G winch on D6N, and was now looking to upgrade to D6T. They needed the precise line control that a hydraulic winch can offer. The new H6H was readily adaptable to both D6N and D6T. Both D6N and D6T can now take either the W6G PTO winch or the H6H hydraulic winch.

Komatsu D61-23 Crawler Dozer

Komatsu has just released their newest crawler dozer, the D61-23, replacing the D61-15. It is a hydrostatic dozer, similar to D51-22. The Allied H6H winch, currently used on D65-16/17, will be offered for this new dozer as well.

Tigercat 635D Grapple Skidder

Allied has been the OEM supplier of skidder winches to Tigercat in Canada for many years. The WH410 winch, a hydraulic derivative of the very successful Allied PTO-driven W400 skidder winch (previously from Clark and Lufkin), is installed on most Tigercat skidders. A recent demand for a more powerful skidding winch on Tigercat's largest skidder, the 635D grapple skidder with rear bogie axle, resulted in a collaborative effort between the Allied and Tigercat engineering teams to adapt the H6H hydraulic towing winch to this log skidder. The H6H gives the 635D both high line pull for rescue work in difficult terrain and fast line speed for production skidding in areas where the terrain is unsuitable for traditional grapple skidding.

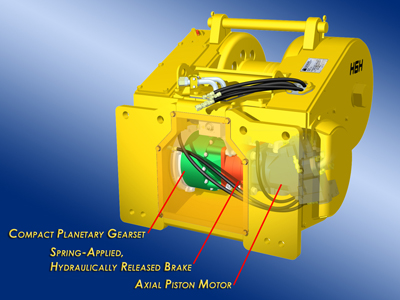

The common theme in all these applications is the Allied H6H winch. With its state-of-the-art variable displacement motor and modular drive train, the winch can be quickly adapted to a wide variety of hydraulic supply systems and control schemes. This flexibility shortens the engineering lead time substantially, allowing Allied to maintain its edge as a responsive supplier to the heavy equipment community.

The H6H hydraulic winch is available for the following crawler dozers and track loaders: |

|

Caterpillar: |

D6N, D6T, 963D |

Komatsu: |

D61-23, D65-16/17 |

John Deere: |

750J/K, 850J/K |

Liebherr: |

PR724 |

The Caterpillar 963D track loader with the Allied H6H winch. A video camera at the top of the radiator grille allows the operator to see the winch in operation.

The Liebherr PR724 now has the option for Allied H6H winch. The "Plug and Play" H6H winch can be installed easily on the pin-mount rear face of the dozer.

The massive Tigercat 635D in a tropical logging environment needed a winch to match. The H6H is perfect for this heavy-duty application.

The H6H winch is based on the very successful W6F and W6G PTO-driven winches. The hydraulic motor is housed inside the winch frame, out of harm's way. Using different hydraulic motor settings and planetary gear ratios, the H6H winch is readily adaptable to a wide variety of hydraulic inputs.