Increasing numbers of John Deere dealers have been asking for a hydraulic winch alternative to fit on their JD450-550-650 and 700 dozers. Many bids specify hydraulic winches. Many applications require the smooth speed control of hydraulic winches. Until now, the only winch readily available for these dozers has been a mechanical winch.

Good news! Allied now offers a hydraulic alternative—the model H4A hydraulic winch.

The JD 450-550-650 and the 700 dozers have traditionally been fitted with the JD4000S winch, a PTO-driven mechanical winch known for its power in forestry applications. But as John Deere small dozers expand their market reach to a wider range of applications such as oil and gas well services, power line sagging, equipment rescue, and construction support, the need for a hydraulic winch alternative becomes apparent.

The H4A hydraulic winch offers significant advantages over the traditional mechanical winch in certain applications.

First is precision control of line speed and the ability to control line placement to a fraction of an inch. A mechanical winch takes the engine power at its PTO output through several winch gear reductions to deliver slower RPM at the winch drum. The only way to smoothly engage the winch drum is to slip the winch clutch. No matter the skill of the operator and the design of the winch, regardless of brand, smooth engagement is always a challenge.

A hydraulic winch, on the other hand, delivers smooth winch engagement and precise speed control. This is especially important in new applications such as power line sagging, cable plowing and spotting equipment down slopes.

Another big plus is smooth gear engagement. Mechanical winches, being directly coupled to the dozer PTO output, are subject to shock loading. Inexperienced operators may overload a mechanical winch, which frequently leads to early failures.

A hydraulic winch, on the other hand, reduces the shock loading to near zero. The winch hydraulic system's pressure relief valve is a built-in limiter to overloading, further reducing the possibilities for failure.

For John Deere dealers, an additional advantage is maintaining competitiveness in the market. Many bids in this dozer class specify hydraulic winch, and many applications require precise control. While competitive dozers like Caterpillar and Komatsu have the option of hydraulic winches available to meet these requirements, John Deere had no easy options. Until now. The arrival of the H4A winch for John Deere small dozers meets the challenge.

All Allied towing winches are engineered from the ground up as a rear-mounted attachment for dozers. As such, they are designed to take the abuse you can expect of an exposed part of a crawler dozer. The H4A frame is built from steel plate, making it less brittle than a cast frame and thus better able to withstand shock loading.

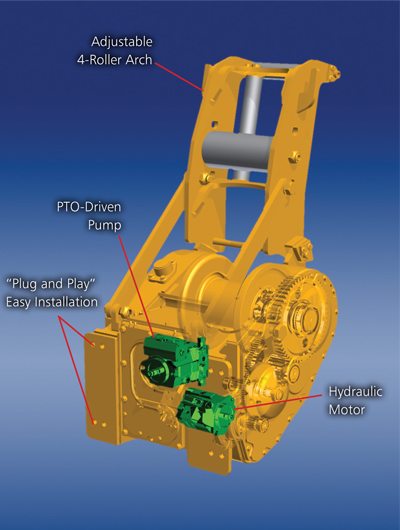

The winch features our Self-Contained Hydraulics (SCH) configuration, where the hydraulic pump and motor are contained inside the winch frame, for protection and winch integrity. You may easily move the winch from one dozer to the next without having to worry about hydraulic system contamination and loose hydraulic parts scattered around outside the winch frame.

Options for the H4A winch include a four-roller fairlead, a bolt-on drawbar, and a logging arch. Logging customers will appreciate having the arch engineered and built specifically for the winch by the same winch manufacturer.

The H4A also makes dealer inventory control simple. It can be installed on 450J, 550J/K and 650J/K dozers. With a simple conversion kit, the H4A winch can also be fitted on the 700H/J/K dozers.

Installing the H4A winch is not much different than installing a 4000S mechanical winch. The H4A winch is powered by the same PTO, which drives the hydraulic pump located inside the H4A winch case. Like the 4000S, the H4A has access to all the horsepower available from the PTO for powerful line pull.

As long as the dozer is fitted with the PTO option (John Deere option code 7975), the winch comes complete with all necessary mounting parts and control lever for simple installation. Control is through a pilot-controlled joystick installed on the operator console. No mechanical adjustment is required.

The first installation of the H4A winch was done on a 450J dozer for John Deere dealer Brandt Tractor in Regina, Saskatchewan, Canada. The service technicians found that the H4A is easier and faster to install than a traditional mechanical winch. They immediately noticed the precise line speed control the H4A delivers.

The 450J has since been shipped to a waiting customer in Fort McMurray, Alberta. This is the center of the Canadian tar sands oil production area. Ground conditions are often very difficult, and dozers used in tar sands work almost always require a winch, primarily for self-rescue and for rescuing other vehicles. The H4A winch is expected to give the 450J smooth pulling capability for easier rescue work.

H4A Winch for JD450-700 |

||

Rating |

40,000 lbs |

18,200 kg |

Line pull, bare drum |

38,200 lbs |

17,400 kg |

Line pull, full drum |

21,300 lbs |

9,700 kg |

Maximum line speed, bare drum |

83 ft/min |

25 m/min |

Maximum line speed, full drum |

149 ft/min |

45 m/min |

Cable capacity |

277 ft |

84 m |

@ wire rope dia. |

5/8 inch |

16 mm |

Weight |

1,680 lbs |

760 kg |

The John Deere 450J equipped with Allied H4A winch. The same winch fits 550J/K and 650J/K. With a different mounting bracket and driveline, it also fits the 700H/J/K.

Brandt Tractor sales rep Matt Haley in Fort McMurray is eager to see the H4A hydraulic winch go into service.

The H4A features Self-Contained Hydraulics (SCH) design. The hydraulic pump and motor are contained inside the winch frame for protection and integrity, and are isolated from the dozer hydraulic system. Winch power comes from the John Deere PTO output.